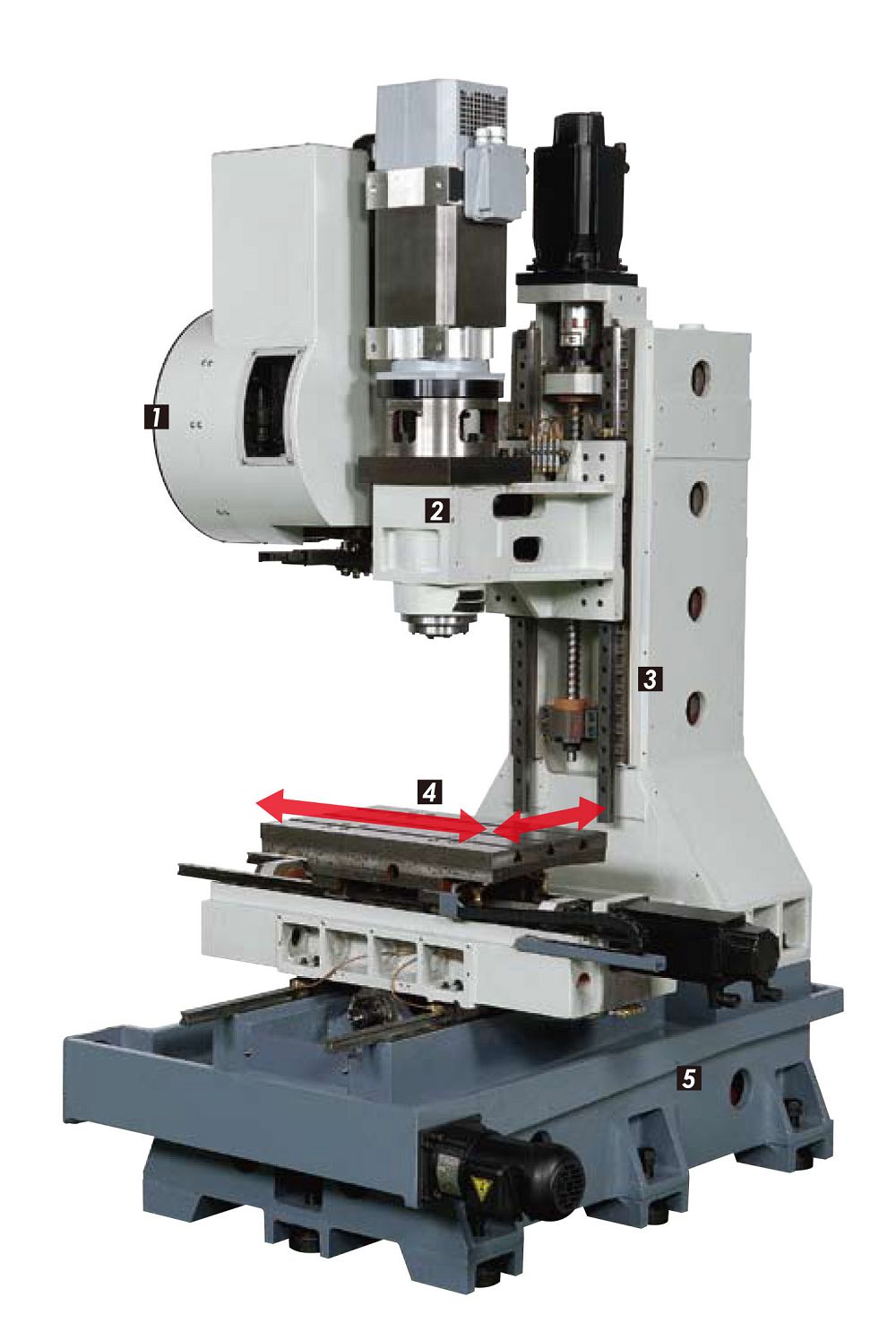

High Speed VMC

| FEATURES | |

|

1.30-taper swing arm 20PC tool changer 2.Powerful direct-drive 10000rpm spindle 3.Robust linear guide ways and ball screw 4.650x400mm working table 5.Rigid cast-iron machine construction |

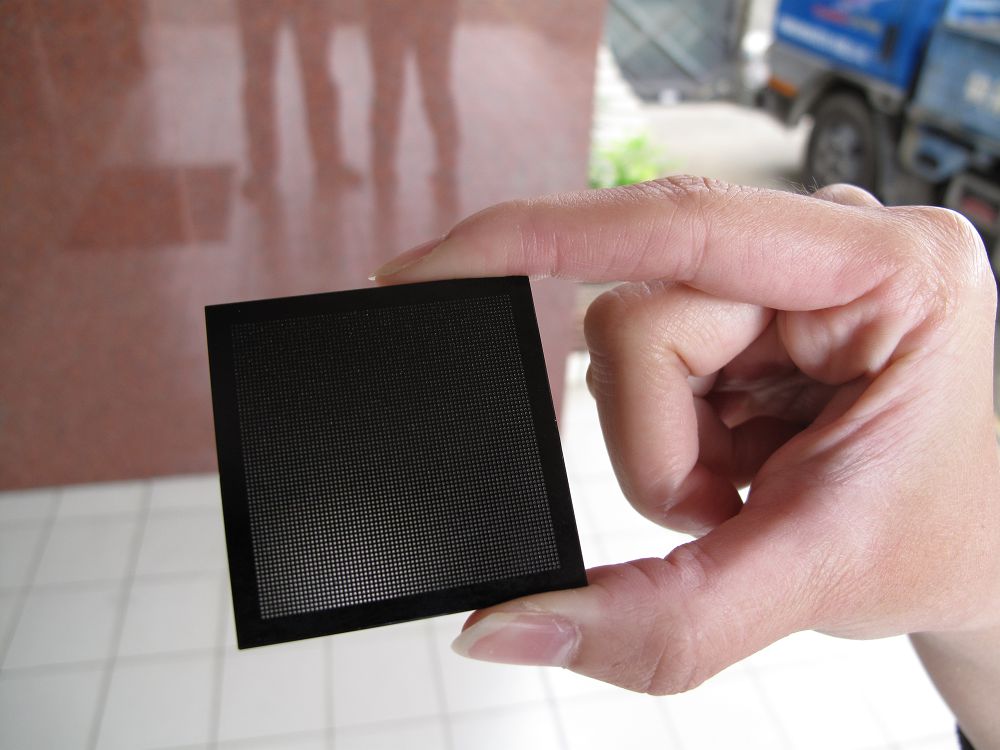

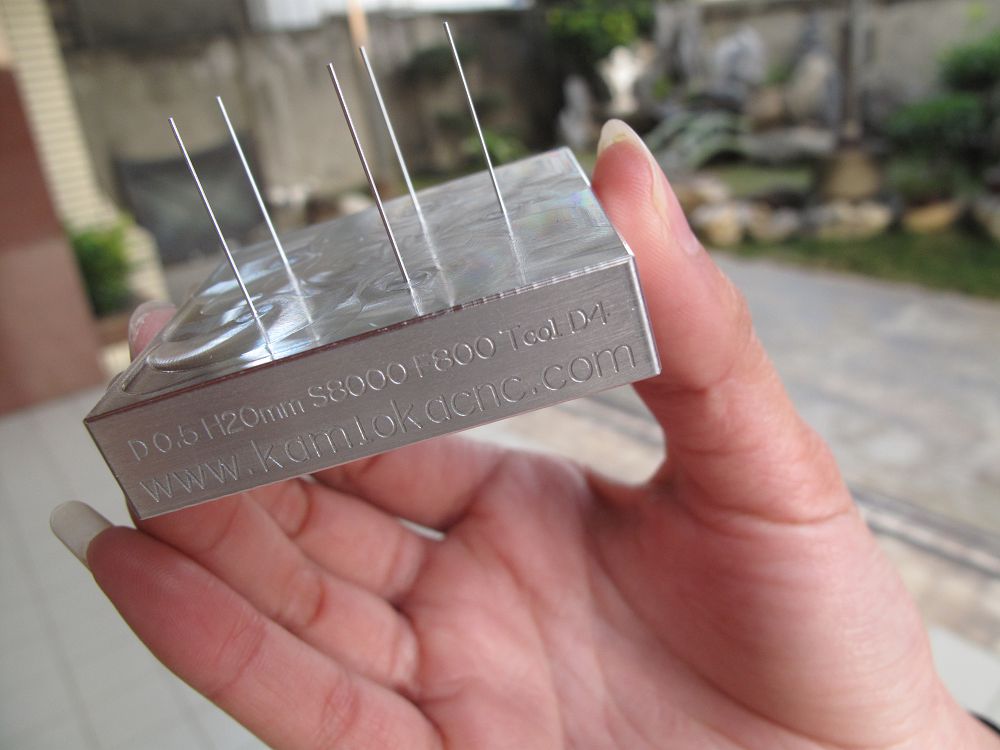

| SAMPLE APPLICATION | ||

|

|

|

| Item/Model No. | Unit | VMC-550 |

| Travel | ||

| X/Y/Z | mm (in.) | 550/400/400 (21.65/15.75/15.75) |

| Z axis-Optional | mm (in.) | - |

| Distance between Columns | mm (in.) | - |

| Table | ||

| Dimension | mm (in.) | 650×400 (23.62×15.75) |

| T-slot (W×No.×CD) | mm | 14×3×100 |

| Max. Table Loading | kg (lb.) | 250 (550) |

| Spindle | ||

| Max. Speed-Standard | rpm | Direct drive 12,000 |

| Max. Speed-Optional | rpm | Built-in 24,000 |

| Spindle Motor | kW (HP) | M: 5.5/7.5 (5/7) |

| Spindle Taper | BT30 | |

| Spindle Nose to Table Surface | mm (in.) | 120~520 (4.72~20.47) |

| Spindle Center to Column | mm (in.) | 430 (16.93) |

| Feedrate | ||

| Cutting Feedrate | mm/min (ipm) | 1~12,000 (0.04~472.44) |

| X axis Rapid Traverse | mm/min (ipm) | 36,000 (1417.32) |

| Y axis Rapid Traverse | mm/min (ipm) | 36,000 (1417.32) |

| Z axis Rapid Traverse | mm/min (ipm) | 36,000 (1417.32) |

| ATC | ||

| Tools Capacity-Standard | pcs | Swing Arm 20 |

| Tools Capacity-Optional | pcs | - |

| Max. Tool Dia. | mm (in.) | ø80 (ø3.15) |

| Max. Tool Length | mm (in.) | 250 (9.84) |

| Max. Tool Weight | kg (lb.) | 7 (15.4) |

| General Information | ||

| Electrical Power Capacity | KVA | 15 |

| Dimension (W×D×H) | mm (in.) | 1,850×2,600×2,450 (72.38×102.36×96.46) |

| Machinery Weight (Net) | kg (lb.) | 3,000 (6,600) |

●STANDARD EQUIPMENT

1. Full Enclosure Splash Guard

2. Three Axes Ball Linear Guide Ways

3. Telescopic Cover on Three Axes

4. Cutting Coolant Unit

5. Auto Lubrication System

6. Air Blast Through Spindle Taper

7. Air Blow

8. Spindle Oil Chiller

9. Heat Exchanger in Electric Cabinet

10. Spiral Type Chip Conveyor with Chip Cart

11. Servo Brake System on Z-axis

12. Work Lamp and Alarm Indicator

13. Service Tools and Leveling Bolts

14. Manual Pulse Generator (Hand-wheel)

15. Mechanical and Electrical Operation Manuals

16. Precision Check Data

17. One Year Warranty for Machine under Normal Operation (From the Date on Bill of Lading)

18. Warranty of Controller depend on Buyer's Location

●OPTIONAL ACCESSORIES

1. Direct-drive 15,000rpm Spindle (3.7/5.5kW, M70)

2. Built-in 24,000rpm Spindle (4.6kW, M70)

3. 4th Axis Preparation

4. 4th Axis Rotary Table

5. Tool Setting Probe

6. Workpiece Measurement

7. Oil Skimmer

8. Air Conditioner in Electric Cabinet

9. Hinge Type Chip Conveyor

10. Transformer

11. Door Interlock

12. CE

* KAMIOKA reserves the right to change design, color or spec without prior notice.