Surface Grinder

| FEATURES | ||

|

|

|

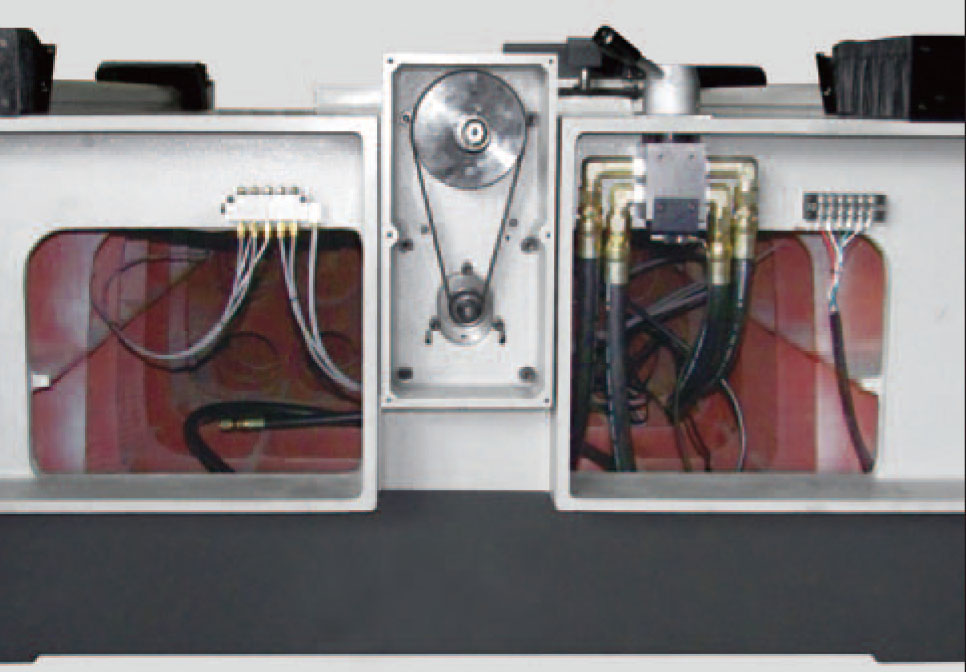

| High rigidity casting components may effectively disperse all reaction force, while absorbing vibration during movement. For mirror-effect grinding on high-hardness materials, such as SKD-11 and tungsten carbide, there is great resistance of grinding. However this machine has been tested to achieve surface roughness of Ra 0.015 um | |||

|

|

||

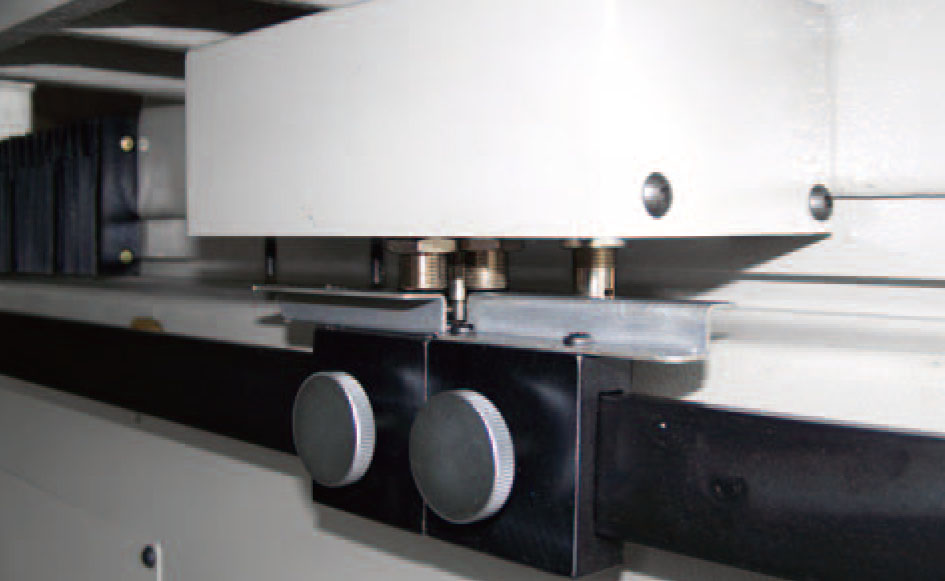

| The cross and longitudinal feed employs 12mm non-contact circular proximity sensor for directional change. Its outstanding dust-proof and water-proof performance is superior to another device | |||

|

|

||

| The cross and longitudinal feed employs 12mm non-contact circular proximity sensor for directional change. Its outstanding dust-proof and water-proof performance is superior to another device | |||

|

|

||

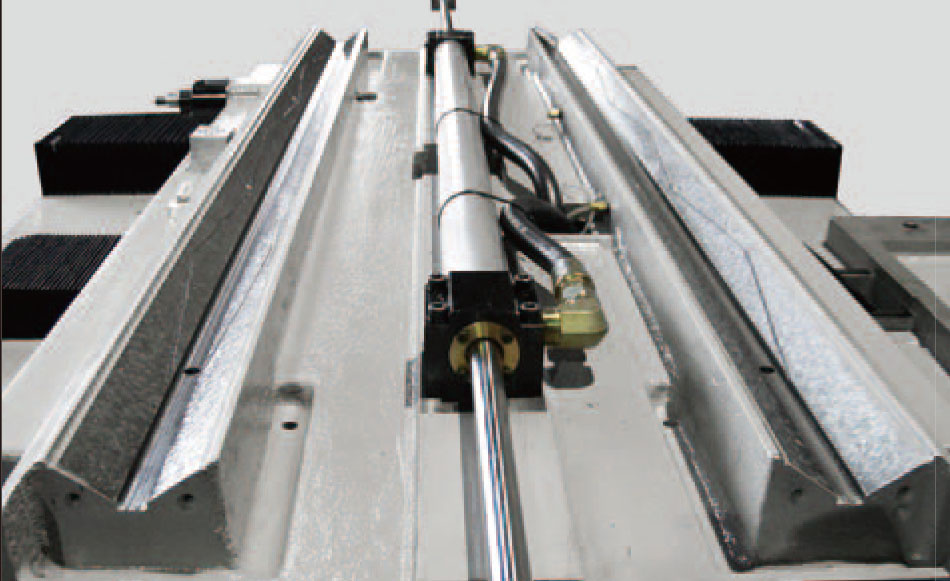

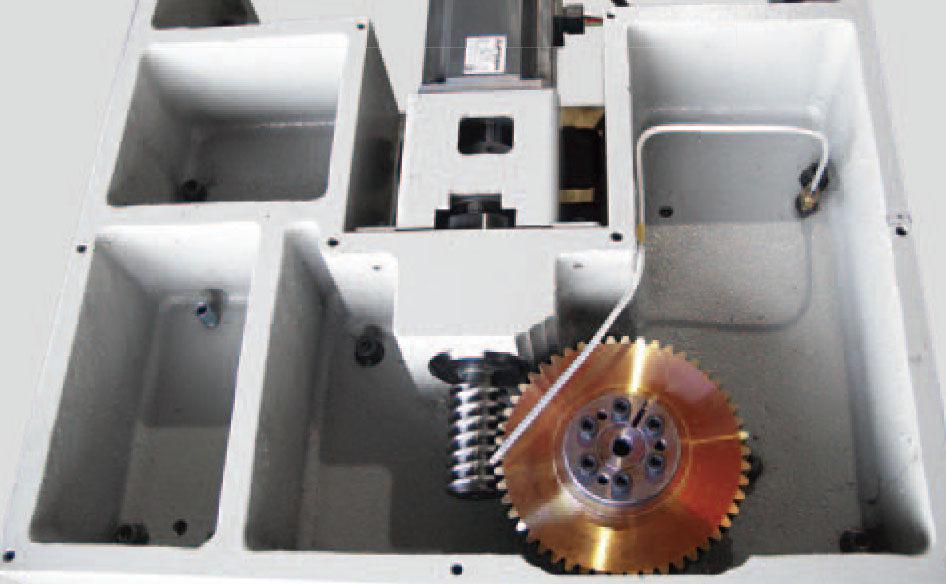

| Y, Z axes are transmitted through 32mm diameter, class C3 precision ball screws with double nuts. | |||

|

|

||

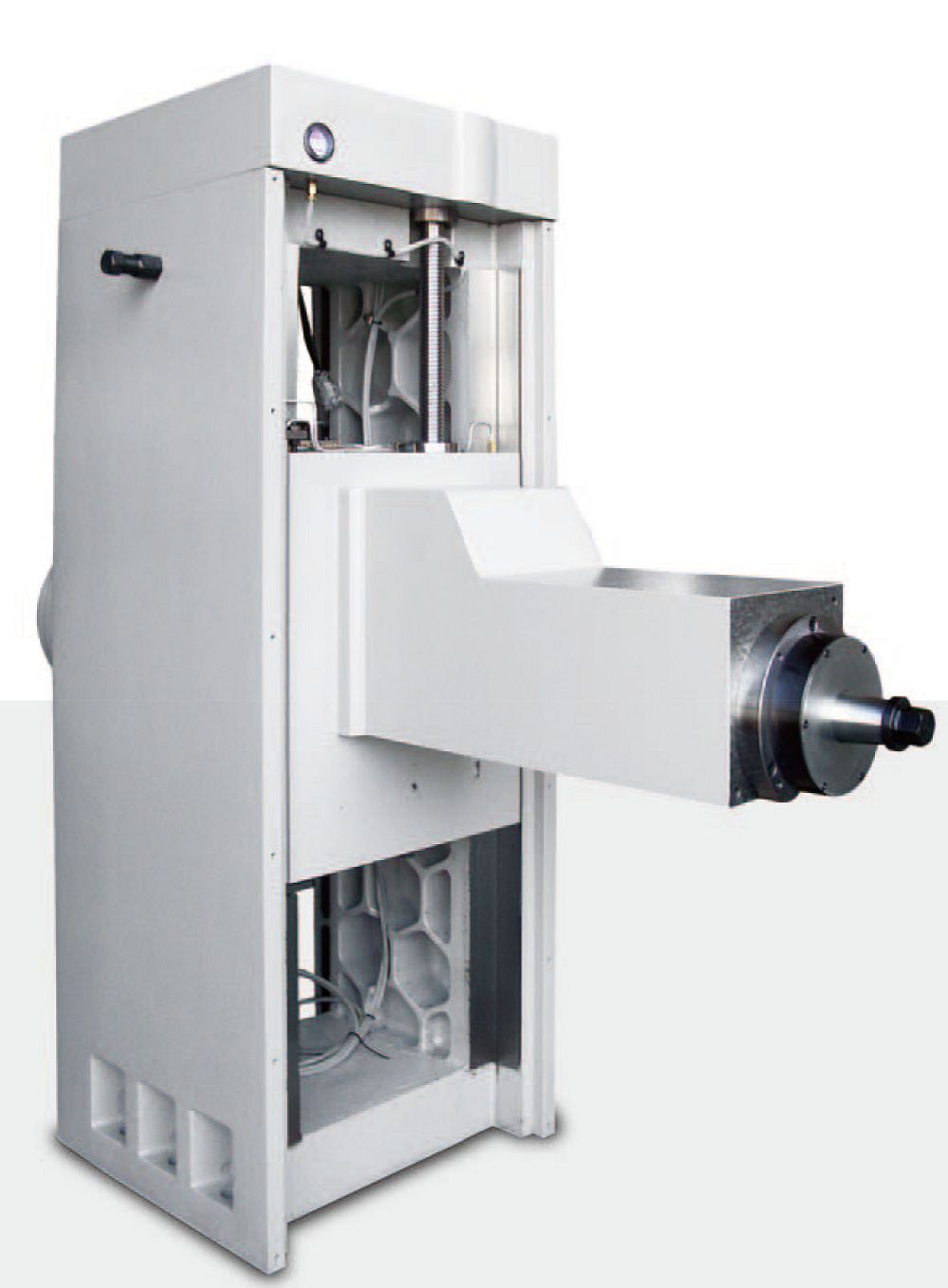

| The spindle head is well balanced on the column. The ball-screw is located at the center of column and the spindle head with weight ratio 5:4. The end face of the spindle head is precision scraped, and is precision mounted when installing the spindle. This will prevent spindle from deformation due to stress | The vertical feed is driven by a 0.75kW servo motor. It drives the precision ground worm through backlash-free coupling that drives a phosphor bronze worm gear. The worm/worm gear set drives the ball screw for vertical feed, that allows for 1um micrometric feed. | ||

| SAMPLE APPLICATION | |

|

Mirror-effect Grinding Test Workpiece Material: SKD-11, Ruche HRC62-degree Workpiece Size: 270x380x Grinding Time: 3.5hours Test Result: Parallelism 2um Flatness 3um Surface Roughness Ra 0.015um |

| Item/Model No. | Unit | 3A4080 |

| Capacity | ||

| Table Size | mm (in.) | 400×800 (15.75×31.5) |

| Longitudinal Travel | mm (in.) | 900 (35.43) |

| Cross Travel | mm (in.) | 450 (17.72) |

| Spindle Center to Table | mm (in.) | 615 (24.21) |

| Magnetic Chuck Size | mm (in.) | OPT. 400×800 (15.75×31.5) |

| Longitudinal Feed | ||

| Manual Travel | mm (in.) | 930 (36.61) |

| Automatic Travel | mm (in.) | 910 (35.83) |

| Table Traverse Rate | M/min | 5~25 |

| Cross Feed | ||

| Manual Travel | mm (in.) | 470 (18.5) |

| Automatic Travel | mm (in.) | 450 (17.72) |

| Automatic Feed (Variable) | mm | 0.5~10 |

| Hand Wheel per Revolution | mm | 5 |

| Hand Wheel per Graduation | mm | 0.02 |

| *Micrometric Adjustment per Revolution | mm | - |

| *Micrometric Adjustment per Graduation | mm | - |

| Rapid Traverse Rate | mm/min (ipm) | 1,000 (39.37) |

| Vertical Feed | ||

| Hand Wheel per Revolution | mm | x=0.1mm,x10=1mm,x20=2mm |

| Hand Wheel per Graduation | mm | x1=0.001mm,x10=0.01mm,x20=0.02mm |

| *Micrometric Adjustment per Revolution | mm | - |

| *Micrometric Adjustment per Graduation | mm | - |

| Rapid Traverse Rate | mm/min (ipm) | 500 (19.69) |

| Automatic Feed (Variable) | mm | - |

| Grinding Wheel | ||

| Grinding Wheel Size (OD×W×BD) | mm | 355×38~50×127 |

| Spindle Speed | rpm | 1,720(60hz) / 1,425(50hz) |

| Motor | ||

| Spindle Motor | kW (HP) | 5.63 (7.5) |

| Hydraulic Motor | kW (HP) | 2.25 (3) |

| Cross Feed Drive | 80W | |

| Vertical Feed Drive | Servo Motor 0.75kW | |

| General Information | ||

| Total Rated Horsepower | kW (HP) | 9 (12) |

| Dimension (W×D×H) | mm (in.) | 2,900×2,200×2,240 (114.17×86.61×88.19) |

| Machinery Weight (Net) | kg (lb.) | 3,600 (7,920) |

●STANDARD EQUIPMENT

1. Ballscrew on Cross Feed and Vertical Feed

2. Water-repellent Shield

3. Wheel and Wheel Flange

4. Wheel Extractor with Wrench

5. Wheel Balancing Arbor

6. Service Tools

7. Diamond Dresser and Base

8. Work Lamp

9. Leveling Blocks with Bolt

10. Lifting Bolt

11. Splash Guard

12. Operation Manual

13. One Year Warranty for Machine under Normal Operation (From the Date on Bill of Lading)

●OPTIONAL ACCESSORIES

1. Permanent Magnetic Chuck

2. Electromagnetic Chuck

3. Chuck Control w/Demagnetizer

4. Coolant System

5. Coolant System w/Magnetic Separator

6. Coolant System w/Paper Feeding Device

7. Dust Collector

8. Roller Type Balancing Stand

9. Spare Grinding Wheel

10. Spare Wheel Flange

11. Manual Parallel Dressing Attachment

12. Hydraulic Unit w/Fan

* KAMIOKA reserves the right to change design, color or spec without prior notice.